I came across some posts by Kamil Galeev in which he discusses the strategic importance of machine tools and the broader concept of building an economy for war. I’m listing these posts here, along with a summary and some of my commentary for each, as many of them are behind a paywall. I’ll keep adding new posts here as I read them on Kamil’s substack and Twitter, so if you want to be updated either follow Kamil or check this page every few weeks or months.

1 On machine tools

1.1 Shift to CNC machines

Substack (behind a paywall)

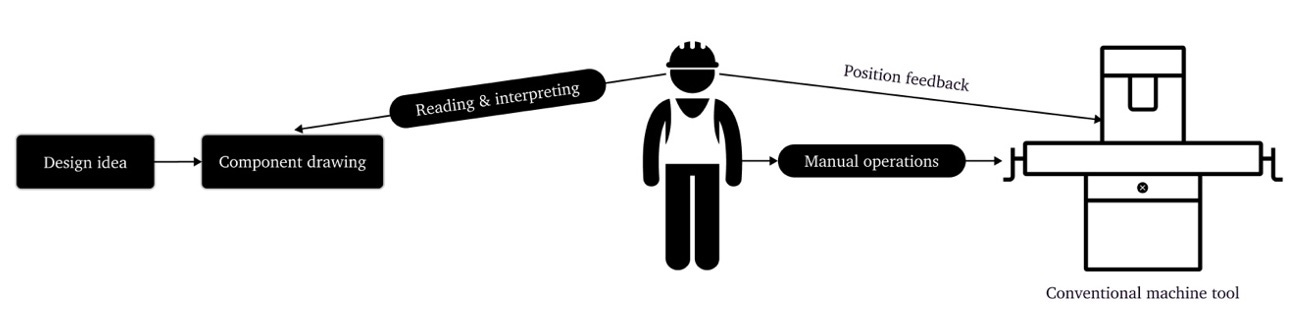

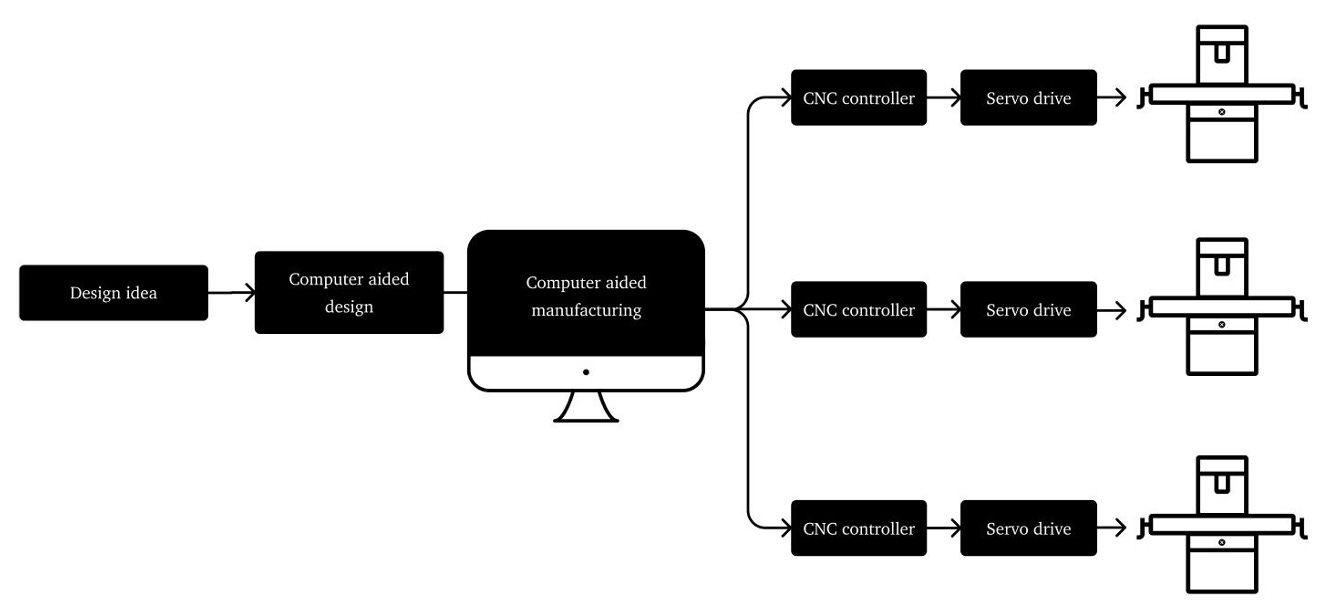

This is a primer on the evolution of manufacturing from manual to digital control systems. It describes a progression that began with manually drawing a blueprint of a component and interpreting it, followed by operating machine tools with human sensory feedback. Starting in the 1960s, this process transitioned to drawing and interpreting blueprints, then programming numerical control (NC) machines by feeding them a perforated tape with instructions, with the NC machine performing the machining. In the 1970s, this evolved into the use of computer numeric control (CNC) machines. Finally, in the 1990s, with the development of Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) software, the process further advanced to creating drawings using CAD software, converting these drawings into instructions for the CNC machine using CAM, and having the CNC machine execute the machining. Each step improved accuracy while also reducing the need for a highly specialized workforce built by passing knowledge from senior workers to juniors through apprenticeship.

1.2 Production chain of the missiles that S400 fires

Substack (not behind a paywall)

Even though the post is on why Russia is winning the war in Ukraine, it’s more of a brief introduction to the production chain of the missiles that Russia’s S400 missile system fires.

Casting - pour molten metal into a mould/die. This step is totally manual.

Pressing, forging, stamping - shape the metal with compressive force to increase its strength or give it a desired form. THis process utilizes machines but they’re fairly old and (I guess) not computer-controlled.

Machining - further remove unwanted material from the pressing-foreging-stamping stage using lathes, milling and drilling machines, etc. This stage is most affected from the transition to digital control, which also leads to asymmetric power among countries, a factor that can be exploited.

Coating - to cover it with a layer to prevent corrosion, increase surface strength or reduce friction, etc. It encompasses a broad range of processes, some of which are automated, while others are not.

Assembly, wiring - the least automated

It’s not behind a paywall and includes video clips showing all processes listed below, so I’d recommend watching them and reading the entire post. The clips have been taken from this video.

In a recent Twitter thread, he shared a graph illustrating the difference in importance of various stages in the production processes of the Sineva SLBM at KrasMash.

I don’t know what the y-axis is. My best guess would be that it’s either time taken by each process or the cost. I think it being time is more probable.

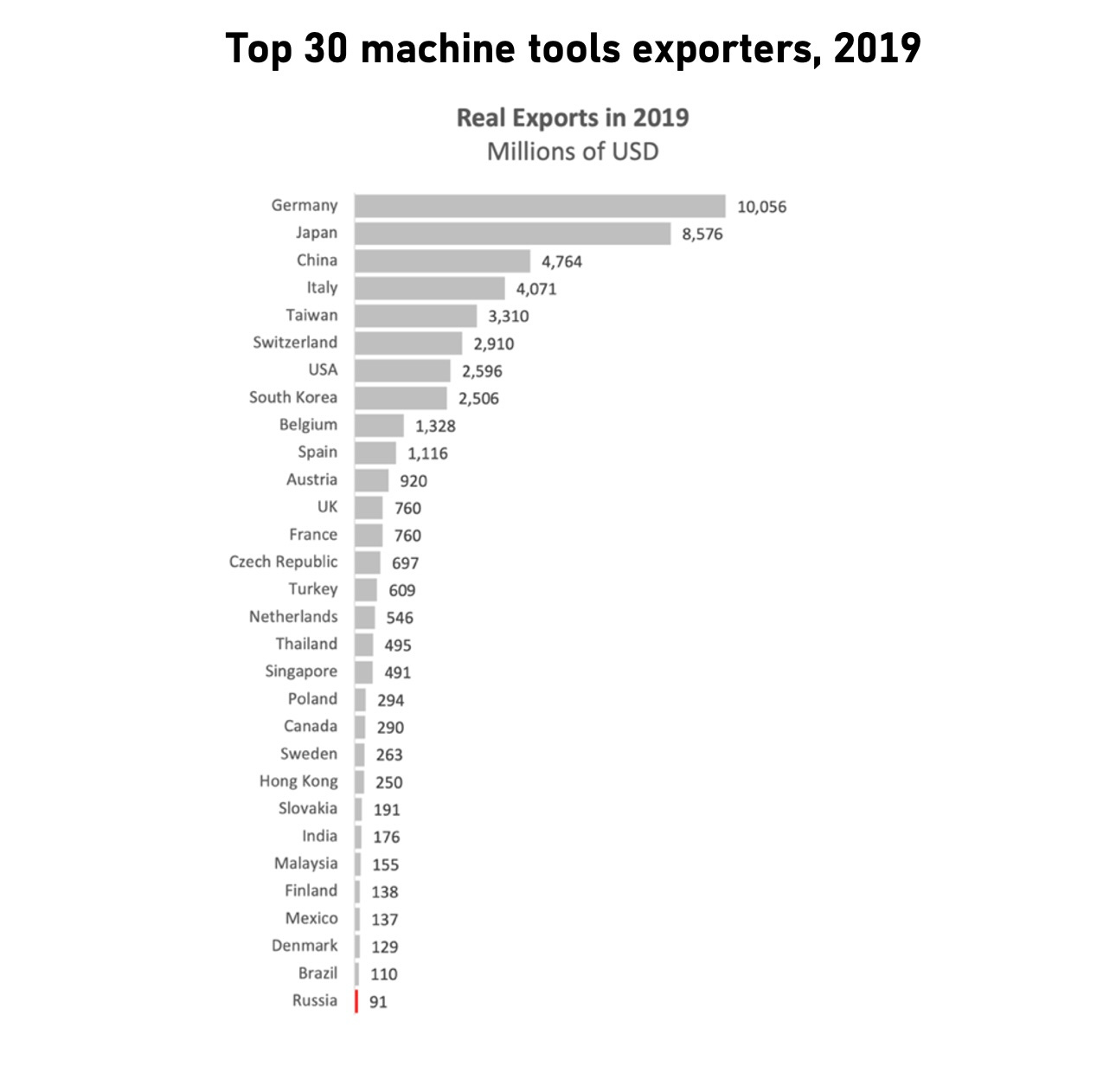

1.3 Asymmetric geographical distribution of machine tools production

Substack (behind a paywall)

The assymetric geographical distribution of machine tools production makes it a strategic chokepoint, given its importance in manufacturing weapon systems and other essential goods in the modern economy. The following figures from the piece effectively capture these regional disparities. (Note that it’s clearly visible in all of the figures that India has a very high dependence for machine tools but also that countries like China and Russia, which are also perceived as military behemoths by some, aren’t in a very good position either.)

| High capacity | Limited capacity | |

|---|---|---|

| High capability | Western Europe, Japan | United States, United Kingdom |

| Limited capability | Taiwan, South Korea, China (heavily limited) | Most industrial countries |

2 Goldilocks zone for wealth creation

2.1 Violent entrepreneurs

Substack (Substack) (behind a paywall), Twitter (not behind a paywall)

Even though a critique on Elon Musk’s peace plan for the Ukaine-Russia conflict (which is not my concern for the purpose of this post), this piece highlights the importance of weeding out “violent entrepreneurs” (straight-up criminals or politically connected insiders who use state machinery to get ahead of non-violent entrepreneurs) in letting “non-violent entrpeneurs” flourish, which is important for wealth creation.

3 On China

3.1 China CANNOT substitute Western machine tool imports

Substack (behind a paywall)

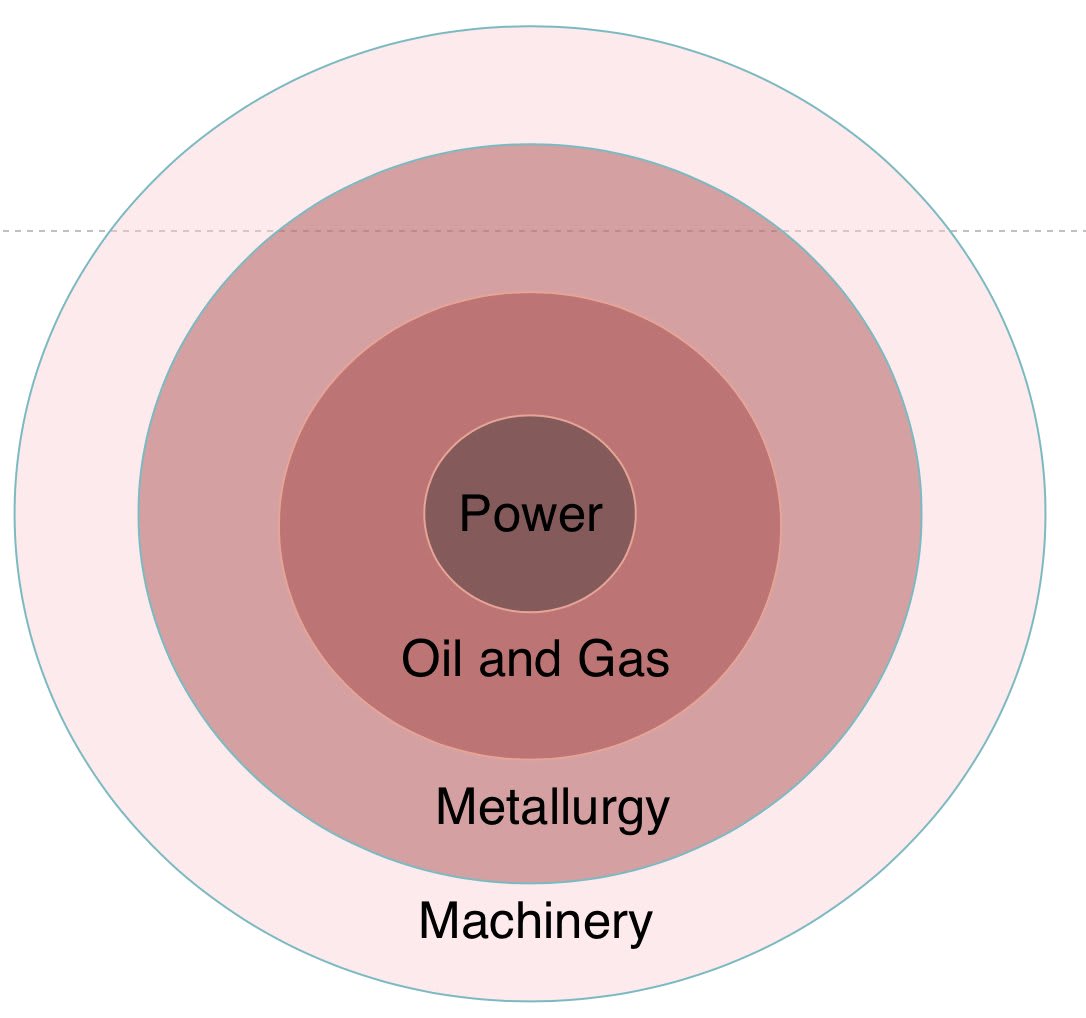

This piece critiques the narrative that Western export controls cannot significantly impact other economies (specifically Russia) because Western exports are smaller compared to China, and China can substitute them. Galeev employs the food chain analogy to explain that certain critical technologies, such as machine tools, may constitute a small percentage of the GDP or exports but are crucial for manufacturing consumer goods and weapon systems. These technologies are at the top of global supply chain even though they constitute a small percentage of the global GDP. This also happens in the animal kingdom, where, as you go higher in the food chain, the aggregate mass of the level drops, for example, in terms of aggregate mass, all the grass on Earth is heavier than all the herbivores, which are heavier than all the carnivores.

3.2 China’s chokepoints (I guess it’s safe to assume that all would also be India’s chokepoints)

An article that Galeev often cites, but did not write himself, is “Chokepoints” on “China’s Self-Identified Strategic Technology Import Dependencies” by Georgetown University’s CSET. This article describes China’s self-identified import dependencies as published in a Chinese state-affiliated newspaper Science and Technology Daily. These range from photo-lithography machines (a more well-known chokepoint for China given the sanctions imposed by the US in the recent past) to aviation design software — a total of 35 technologies. This spreadsheet, attached in the article’s Appendix, contains a list of the technologies, leading global providers, the PRC providers, China’s difficulties, its catch-up efforts, and experts and papers cited.